Pulp Paper Molding Machines ,applied in the egg tray , industrial packaging ,Medical Care products packaging fields .Scales of the whole set machines can be chosen . Customers offer the details and requests of the plant scales , our engineers will evaluate the practical scales and machines integration for you.

Products Applications :

.jpg) .jpg) .jpg) .jpg) .jpg)

Egg tray Toys Electronics package,Food Vessel,Industrial buffer Walls decoration

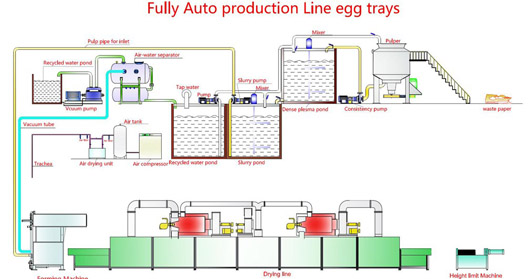

Flow chart of equipment :

A. Pulping System

1.Hydraulic Pulper

Hydrapulper is the core equipment in pulp making system ,with whose hydraulic force ,the raw material is smashed . Then mixing it into water with a certain proportion , the pulp material (which can be used for forming pulp molded products) will be formed.

Based on the Taiwan advanced pulp making technology,we produced a series of hydrapulpers,whose rotator is FU KESI rotator, with stainless steel , tetrastyle base and efficient motor.There are 2 kinds of hydrapulper in our company : horizontal hydrapulper and vertical hydrapulper; 2 kinds of materials : stainless steel and plain steel .

B. Forming Machine

1-station forming machine

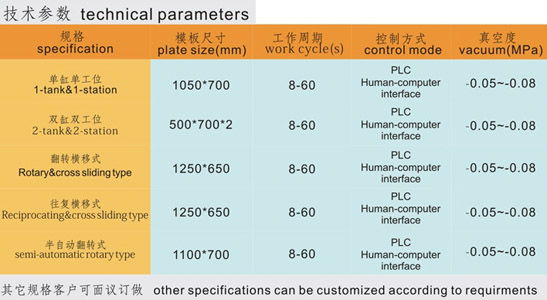

The control system of our forming machine consist of advanced computer programming,PLC and Intelligent touch screen etc. Which make it possible to control forming machine in a long distance. The machine also owning the function of intelligent adjusting mould ,washing mould and adjusting parameter etc. Thus greatly improved the efficiency in forming products and high quality products.

Left/right laterally-moving forming machine ,equipped with two independent pulp tank,this type of machine can produce two or more kinds of products with different type , different thickness and different color etc.

The rotary forming machine is suited for the mass production,especially for such big size,deep products which are better to be produced by sucking pulp reversed. After forming,products can be automatically transformed to the drying line. This kind of machine have high production efficiency and excellent performance.

Our company manufactured 3-station forming machine,which contains forming ,drying,hot press and trimming etc. This type of machine is better to produce high quality products.

With high automaticity,such machine can work without many worker and cover small area .

8-sides automatic forming machine is suited for such mass and simple structured products . Such as egg tray, fruit tray coffee cup tray etc. Besides, there are 4-sides forming machine etc.

C. Automatic air/water separator

Automatic air/water separator is a machine which supports the using of forming machine.Its main function is to store vacuum and make the absorbed water and vacuum separate automatically,thus achieving automatic drain. The machine adopts Taiwan brand hydraulic controller ,working stably and easy to repair .

Drying System

Applied to dry the produtcs after forming

Multi level, smaller occupation,lower energy consumption, for pulp molding use only

Mould

Forming Mould: Down Mould Aluminum Alloy covered with stainless steel net, Upper Mould ABS,1 mould 2 cavities.Shaping mould , 1mould 1 cavity.

Steel Mesh

We look ourselves as a complete solution supplier in the Pulp Molding Industry and we offer service in the following areas:

1)Pulp molding machine manufacturing.

2)Tool and Die Set manufacturing.

3)Raw Material Engineering.

4)Packaging Product Development.

5)Project Management / Turnkey.

6)Training and transfer of know-how.(tooling)

TOP |

|