Die Casting Parts

Orientex Engineering also adopt our own die casting machines to customize producing various kinds of die casting products .When customers sending the drawings to us , we can design the mold and produce them out .Products include:Aluminum Die Casting,Magnesium Die Casting,Zinc Die Casting.

We can produce die castings with kinds of material, such as carbon steel and alloy steel, stainless steel , grey iron, ductile iron, aluminum, brass as well as bronze.Besides, it is also available for us to supply a series of finish steps for the rough casting and metal parts, such as finish machining, welding, heat treating,caseharden, plating, anodizing ,painting etc. Moreover, thanks to our many qualified suppliers for the rubber, plastic injectiong molding,spring, punching,stamping products, that enable us to provide our customers the complete set projects while assembling the correlative products if customers request.

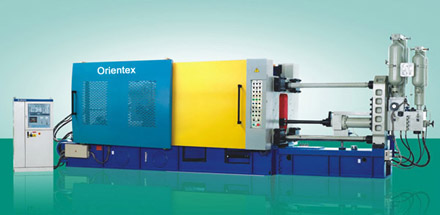

Die Casting Machines

A.Cold Chamber Die Casting Machines

OT150 OT180 OT450 OT1000

Other machines,please contact us

We produce the cold chamber die casting machines ranging from 150ton to 3500 ton clamping force 150ton, 160ton, 180ton, 200ton, 230ton, 300ton, 350ton, 450ton, 550ton, 650ton, 750ton, 850ton, 950ton, 1100ton, 1300ton, 1600ton, 2000ton, 2600ton, 3000ton, 3500ton.For more information ,please contact us by email or download from our website.

Suitable for casting variety of aluminum alloy, copper alloy castings such as home electrical appliances, hand tools, electrical motors, pneumatic/hydraulic/filtration components, computer equipment, auto-motive and motor cycle components etc.

OT150

| Mode |

Unit |

OT150 |

| Die locking force |

KN |

1500 |

| Space between tie bars |

mm |

480*480 |

| Tie bar diameter |

mm |

Φ85 |

| Die thickness(Min-Max) |

mm |

200~550 |

| Locking stroke |

mm |

350 |

| Ejection stroke |

mm |

85 |

| Ejection force |

KN |

100 |

| Injection force |

KN |

180 |

| Injection position |

mm |

0-100 |

| Plunger diameter |

mm |

40 50 |

| Injection weight |

KG |

0.8 1.3 |

| Casting pressure (Intensifg.) |

Mpa |

143 91 |

| Casting area |

cm2 |

104 164 |

| Max.Casting area (40Mpa) |

cm2 |

375 |

| Plunger penetration |

mm |

120 |

| Casting flange diameter |

mm |

Φ110 |

| Height of pressure chamber flange |

mm |

10 |

| Injection stroke |

mm |

340 |

| Dry cycle |

S |

7 |

| System working pressure |

Mpa |

12 |

| Motor power |

KW |

11 |

| Oil tank capacity |

L |

350 |

| Machine weight |

KG |

6200 |

| Machine dimensions(L*W*H) |

m |

5*1.2*2.3 |

OT180

| Mode |

Unit |

SJ180 |

| Die locking force |

KN |

1800 |

| Space between tie bars |

mm |

480*480 |

| Tie bar diameter |

mm |

Φ85 |

| Die thickness(Min-Max) |

mm |

200~550 |

| Locking stroke |

mm |

380 |

| Ejection stroke |

mm |

85 |

| Ejection force |

KN |

108 |

| Injection force |

KN |

265 |

| Injection position |

mm |

0-140 |

| Plunger diameter |

mm |

50 60 |

| Injection weight |

KG |

1.3 1.8 |

| Casting pressure (Intensifg.) |

Mpa |

135 93 |

| Casting area |

cm2 |

133 193 |

| Max.Casting area (40Mpa) |

cm2 |

450 |

| Plunger penetration |

mm |

135 |

| Casting flange diameter |

mm |

Φ110 |

| Height of pressure chamber flange |

mm |

10 |

| Injection stroke |

mm |

355 |

| Dry cycle |

S |

7 |

| System working pressure |

Mpa |

14 |

| Motor power |

KW |

15 |

| Oil tank capacity |

L |

500 |

| Machine weight |

KG |

7500 |

| Machine dimensions(L*W*H) |

m |

5.6*1.2*2.5 |

OT450

| Mode |

Unit |

OT450 |

| Die locking force |

KN |

4500 |

| Space between tie bars |

mm |

660*660 |

| Tie bar diameter |

mm |

Φ130 |

| Die thickness(Min-Max) |

mm |

300~750 |

| Locking stroke |

mm |

550 |

| Ejection stroke |

mm |

125 |

| Ejection force |

KN |

125 |

| Injection force |

KN |

450 |

| Injection position |

mm |

0-200 |

| Plunger diameter |

mm |

60 70 80 |

| Injection weight |

KG |

2.8 3.8 5.0 |

| Casting pressure (Intensifg.) |

Mpa |

159 116 89 |

| Casting area |

cm2 |

283 387 505 |

| Max.Casting area (40Mpa) |

cm2 |

1125 |

| Plunger penetration |

mm |

220 |

| Casting flange diameter |

mm |

Φ130 |

| Height of pressure chamber flange |

mm |

15 |

| Injection stroke |

mm |

540 |

| Dry cycle |

S |

10 |

| System working pressure |

Mpa |

14 |

| Motor power |

KW |

22 |

| Oil tank capacity |

L |

850 |

| Machine weight |

KG |

19000 |

| Machine dimensions(L*W*H) |

m |

7.1*1.8*2.95 |

OT1000

| Mode |

Unit |

OT1000 |

| Die locking force |

KN |

10000 |

| Space between tie bars |

mm |

1030*1030 |

| Tie bar diameter |

mm |

Φ200 |

| Die thickness(Min-Max) |

mm |

450~1150 |

| Locking stroke |

mm |

880 |

| Ejection stroke |

mm |

200 |

| Ejection force |

KN |

500 |

| Injection force |

KN |

865 |

| Injection position |

mm |

0-300 |

| Plunger diameter |

mm |

90 110 110 120 |

| Injection weight |

KG |

9.9 12 14.8 17.5 |

| Casting pressure (Intensifg.) |

Mpa |

136 110 91 76 |

| Casting area |

cm2 |

735 909 1096 1315 |

| Max.Casting area (40Mpa) |

cm2 |

2500 |

| Plunger penetration |

mm |

300 |

| Casting flange diameter |

mm |

Φ240 |

| Height of pressure chamber flange |

mm |

20 |

| Injection stroke |

mm |

800 |

| Dry cycle |

S |

16 |

| System working pressure |

Mpa |

14 |

| Motor power |

KW |

45 |

| Oil tank capacity |

L |

1900 |

| Machine weight |

KG |

70000 |

| Machine dimensions(L*W*H) |

m |

10.6*3.5*3.8 |

B. Hot Chamber Die Casting Machines

150KN to 950 KN Major technical parameters table:

|

unit |

150A\B |

OT160B |

OT180B/C |

OT200B |

OT280D |

OT350 |

OT450 |

OT550B |

OT650 |

OT750B |

OT850 |

OT950 |

Die locking force

|

kN |

1500 |

1600 |

1800 |

2000 |

2800 |

3500 |

4500 |

5500 |

6500 |

7500 |

8500 |

9500 |

Die DimensionH×V |

mm |

700×680 |

720×710 |

730×730 |

760×740 |

900×860 |

960×920 |

1050×1010 |

1150×1120 |

1260×1230 |

1360×1360 |

1400×1400 |

1480×1480 |

Between tie Fbars |

mm |

440×440 |

460×460 |

480×480 |

490×490 |

560×560 |

600×600 |

660×660 |

760×760 |

810×810 |

850×850 |

910×910 |

980×980 |

Tie bar diameter |

mm |

80 |

85 |

85 |

90 |

110 |

120 |

130 |

140 |

160 |

170 |

185 |

190 |

Diethickness(Min-Max) |

mm |

200~550 |

200~550 |

200~550 |

200~550 |

250~650 |

250~700 |

300~750 |

320~800 |

350~900 |

350~900 |

400~950 |

400~950 |

Die stroke |

mm |

350 |

360 |

380 |

380 |

450 |

500 |

550 |

580 |

650 |

680 |

760 |

800 |

Ejection stroke |

mm |

80 |

80 |

80 |

80 |

100 |

110 |

120 |

120 |

160 |

160 |

180 |

180 |

Ejection stoke |

kN |

100 |

100 |

100 |

110 |

140 |

160 |

200 |

220 |

250 |

300 |

360 |

360 |

Ejection force |

kN |

180 |

200 |

220 |

230 |

300 |

370 |

450 |

520 |

620 |

680 |

750 |

800 |

Position of pressure injection |

mm |

0,-70,-140 |

0,-70,-140 |

0,-70,-140 |

0,-70,-140 |

0,-160 |

0,-160 |

0,-200 |

0,-220 |

0,-250 |

0,-250 |

0,-250 |

0,-250 |

Diiameter of shot sleeve |

mm |

40,50,60 |

40.50,60 |

50,60,70 |

50,60,70 |

50,60,70 |

50,60,70 |

60,70,80 |

70,80,90 |

80,90,100 |

80~110 |

80~120 |

90~130 |

Dosage of fluid metal pershot(AL) |

kg |

1.8 |

1.8 |

2.2 |

2.5 |

3.2 |

3.8 |

5 |

6 |

9.6 |

11.6 |

16 |

18 |

Injection pressure |

MPa |

143 ~ 63 |

159 ~70 |

112 ~57 |

117~59 |

152~78 |

188~96 |

159~ 89 |

135~81 |

123~79 |

135~71.5 |

149~66 |

125~60.3 |

Projection area of casting |

cm2 |

104 ~ 238 |

100~ 228 |

160 ~ 315 |

170 ~ 338 |

184~ 358 |

186 ~ 364 |

283 ~ 505 |

407 ~ 679 |

528 ~ 822 |

555~1048 |

570~1287 |

760~1575 |

Biggist projection acreage |

cm2 |

375 |

400 |

450 |

500 |

700 |

875 |

1125 |

1375 |

1625 |

1875 |

2125 |

2375 |

Over Height of flange |

mm |

10-0.05 |

10-0.05 |

10-0.05 |

10-0.05 |

12-0.05 |

12-0.05 |

15-0.05 |

15-0.05 |

15-0.05 |

15-0.05 |

20-0.05 |

20-0.05 |

Diameter Of pressure Chamber flange |

mm |

φ110 |

φ110 |

φ110 |

φ110 |

φ110 |

φ110 |

φ130 |

φ130 |

φ165 |

φ165 |

φ180 |

φ190 |

Plunger penetration |

mm |

120 |

120 |

130 |

130 |

150 |

180 |

220 |

230 |

280 |

280 |

300 |

300 |

Injection stoke |

mm |

340 |

345 |

350 |

350 |

420 |

480 |

540 |

570 |

650 |

700 |

750 |

750 |

Dry cycle |

S |

7 |

7 |

7 |

7 |

10 |

10 |

10 |

12 |

13 |

13 |

14 |

14 |

Pipe line pressure |

MPa |

14 |

14 |

14 |

14 |

14 |

14 |

14 |

14 |

14 |

14 |

14 |

14 |

Motor Power |

KW |

11 |

11 |

15 |

15 |

18.5 |

22 |

22 |

30 |

37 |

37 |

37 |

45 |

Volume of oil |

L |

450 |

500 |

600 |

650 |

750 |

800 |

900 |

1100 |

1200 |

1400 |

1500 |

1600 |

Machine weight |

kg |

6200 |

7000 |

7600 |

8200 |

12600 |

14500 |

19000 |

23000 |

30000 |

35000 |

40000 |

48000 |

Overall dimensions |

m |

5×1.3×2.3 |

5.2×1.3×2.35 |

5.6×1.32×2.45 |

5.8×1.4×2.5 |

6.4×1.6×2.7 |

6.8×1.7×2.8 |

7.0×1.9×3.0 |

7.2×2.0×3.2 |

150KN to 950 KN Major technical parameters table:

|

unit |

OT1100 |

OT1300 |

OT1600 |

OT2000 |

OT2600 |

OT3200 |

Die locking force

|

kN |

11000 |

13000 |

16000 |

20000 |

28000 |

32000 |

Die DimensionH×V |

mm |

1620×1600 |

1780×1770 |

1990×2011 |

2110×2235 |

2560×2410 |

2800×2650 |

Between tie Fbars |

mm |

1050×1050 |

1100×1100 |

1250×1250 |

1350×1350 |

1650×1500 |

1800×1650 |

Tie bar diameter |

mm |

210 |

230 |

260 |

290 |

330 |

360 |

Diethickness(Min-Max) |

mm |

450~1150 |

550~1200 |

600~1320 |

650~1600 |

750~1800 |

800~2200 |

Die stroke |

mm |

900 |

1000 |

1100 |

1400 |

1500 |

1500 |

Ejection stroke |

mm |

190 |

200 |

250 |

300 |

320 |

320 |

Ejection stoke |

kN |

500 |

570 |

620 |

650 |

800 |

900 |

Ejection force |

kN |

950 |

1100 |

1300 |

1500 |

1800 |

2100 |

Position of pressure injection |

mm |

0,-300 |

0,-320 |

0,-350 |

0,-350 |

0,-400 |

0,-500 |

Diiameter of shot sleeve |

mm |

90~130 |

100~140 |

110~150 |

130~170 |

140~180 |

150~200 |

Dosage of fluid metal pershot(AL) |

Kg |

20 |

26 |

32 |

42 |

50 |

68 |

Injection pressure |

MPa |

149~71.6 |

140~71.4 |

136.8~73.6 |

113~66 |

117~71 |

118~66.8 |

Projection area of casting |

cm2 |

738~1536 |

928~1820 |

1169~2173 |

1770~3030 |

2222~3662 |

2711~4790 |

Biggist projection acreage |

(40mpa)cm2 |

2750 |

3250 |

4000 |

5000 |

6500 |

8000 |

Over Height of flange |

mm |

20-0.05 |

25-0.05 |

25-0.05 |

25-0.05 |

30-0.05 |

30-0.05 |

Diameter Of pressure Chamber flange |

mm |

φ240 |

φ240 |

φ260 |

φ260 |

φ280 |

φ280 |

Plunger penetration |

mm |

300 |

350 |

380 |

400 |

450 |

540 |

Injection stoke |

mm |

850 |

950 |

980 |

1000 |

1050 |

1200 |

Dry cycle |

S |

16 |

19 |

22 |

25 |

28 |

30 |

Pipe line pressure |

MPa |

14 |

14 |

14 |

14 |

16 |

16 |

Motor Power |

KW |

55 |

37×2 |

45×2 |

55×2 |

55+75 |

75+90 |

Volume of oil |

L |

1800 |

2200 |

2600 |

3000 |

3500 |

3800 |

Machine weight |

Kg |

70000 |

90000 |

110000 |

140000 |

205000 |

250000 |

Overall dimensions |

m |

11×3.3×4.2 |

12.5×3.5×4 |

13×4×4.2 |

14×4.2×4.5 |

15×4.9×5.0 |

16×5.2×5.2 |

TOP |

|